-

Addressing Pharmaceutical Cleaning Challenges with Ultrasonic Cleaning Technology

Addressing Pharmaceutical Cleaning Challenges with Ultrasonic Cleaning Technology

Introduction The pharmaceutical industry faces unique cleaning challenges due to stringent regulations, the need for high levels of cleanliness, and the necessity to prevent contamination in drug production. Ultrasonic cleaning technology has emerged a

-

How to Identify Fake Ultrasonic Cleaners: The Ultimate Authentication Guide

How to Identify Fake Ultrasonic Cleaners: The Ultimate Authentication Guide

Shocking Fact: Lab tests show 1 in 3 budget "ultrasonic cleaners" are completely non-functional! Learn to spot counterfeits before they damage your valuables. Core Identification Methods 1.Transducer Inspection (The Heart of the Machin

-

Ultrasonic Cleaner Intensity Testing: 5 Proven Methods for Accurate Measurement

Ultrasonic Cleaner Intensity Testing: 5 Proven Methods for Accurate Measurement

1. Why Test Ultrasonic Cleaner Intensity? Impact on cleaning efficiency: Low intensity = poor contaminant removal; excessive intensity = part damage Industry standards: ISO 17223:2014 for ultrasonic power measurement

-

How to Modify Ultrasonic Cleaner Power: A Comprehensive Guide for Safe and Effective Adjustments

How to Modify Ultrasonic Cleaner Power: A Comprehensive Guide for Safe and Effective Adjustments

Introduction to Ultrasonic Cleaner Power Adjustment Understanding power modification is crucial for tailoring cleaning performance to specific tasks. This guide covers legal, technical, and safety aspects of adjusting ultrasonic cleaner output (typical

-

How Ultrasonic Cleaners Meet the Stringent Standards for Medical Equipment Cleaning

How Ultrasonic Cleaners Meet the Stringent Standards for Medical Equipment Cleaning

Introduction Medical equipment cleaning demands extremely high standards to prevent cross-contamination, ensure patient safety, and maintain healthcare hygiene. Ultrasonic cleaning machines have emerged as a critical tool in meeting these stringent sta

-

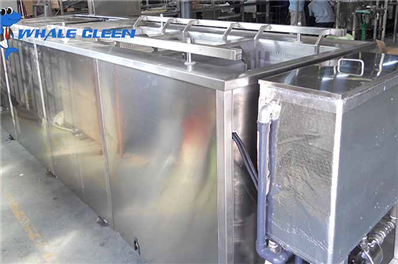

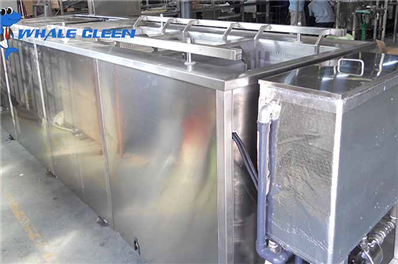

Ensuring Hygiene in Food Production: The Role of Ultrasonic Cleaners

Ensuring Hygiene in Food Production: The Role of Ultrasonic Cleaners

Introduction In the food production industry, maintaining high standards of hygiene is critical to ensuring the safety and quality of food products. Contaminated equipment and surfaces can lead to foodborne illnesses and compromise consumer health. Ult

-

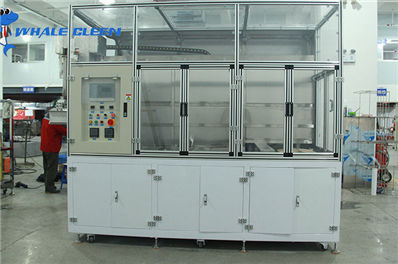

Meeting High Standards of Cleanliness for Electronic Products with Ultrasonic Cleaning Machines

Meeting High Standards of Cleanliness for Electronic Products with Ultrasonic Cleaning Machines

Introduction In the electronics industry, the cleanliness of components and assemblies is paramount. Contaminants such as dust, oils, fingerprints, and residues can significantly affect the performance, reliability, and lifespan of electronic devices.

-

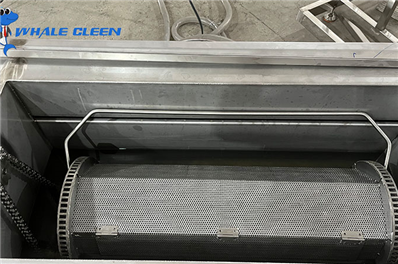

Ultrasonic Cleaning Equipment: Meeting Hygiene Standards in Food Processing Equipment

Ultrasonic Cleaning Equipment: Meeting Hygiene Standards in Food Processing Equipment

Maintaining hygiene in food processing is crucial for ensuring food safety and preventing contamination. One of the advanced technologies that has significantly improved the cleaning processes in the food industry is ultrasonic cleaning equipment. This ar

-

Professional Solutions for Ultrasonic Cleaning of Electronic Component Soldering

Professional Solutions for Ultrasonic Cleaning of Electronic Component Soldering

Ultrasonic cleaning equipment is a critical tool in the electronics manufacturing industry, particularly for cleaning electronic components and solder joints. This technology offers a highly efficient and effective solution for removing contaminants from

-

Determining Optimal Cleaning Time for Ultrasonic Cleaning of Aluminum Parts

Determining Optimal Cleaning Time for Ultrasonic Cleaning of Aluminum Parts

Ultrasonic cleaning machines are widely used in various industries for cleaning metal parts, including aluminum components. Aluminum parts often accumulate contaminants such as oils, greases, metal fines, and oxides during manufacturing processes, which c

-

Efficient Clean Tool: The Application of Ultrasonic Cleaning Machine in Cosmetic Production

Efficient Clean Tool: The Application of Ultrasonic Cleaning Machine in Cosmetic Production

In the modern cosmetic production industry, ensuring product quality and adhering to stringent hygiene standards are paramount for maintaining a brand's reputation and market position. As the industry evolves, the cleaning process has become increasin

-

Ultrasonic Cleaning Machines: Transforming 3D Printing Post-Processing

Ultrasonic Cleaning Machines: Transforming 3D Printing Post-Processing

The 3D printing industry has witnessed significant growth in recent years, revolutionizing manufacturing processes across various sectors. However, post-processing steps, including cleaning, remain crucial to ensure the quality and functionality of printe

Addressing Pharmaceutical Cleaning Challenges with Ultrasonic Cleaning Technology

Addressing Pharmaceutical Cleaning Challenges with Ultrasonic Cleaning Technology

How to Identify Fake Ultrasonic Cleaners: The Ultimate Authentication Guide

How to Identify Fake Ultrasonic Cleaners: The Ultimate Authentication Guide

Ultrasonic Cleaner Intensity Testing: 5 Proven Methods for Accurate Measurement

Ultrasonic Cleaner Intensity Testing: 5 Proven Methods for Accurate Measurement

How to Modify Ultrasonic Cleaner Power: A Comprehensive Guide for Safe and Effective Adjustments

How to Modify Ultrasonic Cleaner Power: A Comprehensive Guide for Safe and Effective Adjustments

How Ultrasonic Cleaners Meet the Stringent Standards for Medical Equipment Cleaning

How Ultrasonic Cleaners Meet the Stringent Standards for Medical Equipment Cleaning

Ensuring Hygiene in Food Production: The Role of Ultrasonic Cleaners

Ensuring Hygiene in Food Production: The Role of Ultrasonic Cleaners

Meeting High Standards of Cleanliness for Electronic Products with Ultrasonic Cleaning Machines

Meeting High Standards of Cleanliness for Electronic Products with Ultrasonic Cleaning Machines

Ultrasonic Cleaning Equipment: Meeting Hygiene Standards in Food Processing Equipment

Ultrasonic Cleaning Equipment: Meeting Hygiene Standards in Food Processing Equipment

Professional Solutions for Ultrasonic Cleaning of Electronic Component Soldering

Professional Solutions for Ultrasonic Cleaning of Electronic Component Soldering

Determining Optimal Cleaning Time for Ultrasonic Cleaning of Aluminum Parts

Determining Optimal Cleaning Time for Ultrasonic Cleaning of Aluminum Parts

Efficient Clean Tool: The Application of Ultrasonic Cleaning Machine in Cosmetic Production

Efficient Clean Tool: The Application of Ultrasonic Cleaning Machine in Cosmetic Production

Ultrasonic Cleaning Machines: Transforming 3D Printing Post-Processing

Ultrasonic Cleaning Machines: Transforming 3D Printing Post-Processing